The principle of zinc spraying and aluminium spraying for corrosion proof on the surface of steel structure

1.0 The principle of zinc spraying and aluminium spraying for corrosion proof of steel structure.

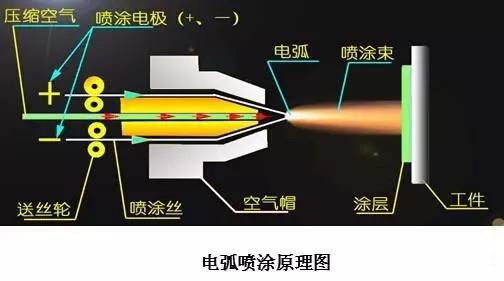

The application of arc spraying is the most popular in the zinc spraying and aluminum spraying corrosion protection of steel structure, and its application prospect is more extensive. The principle of arc spray corrosion proof is making use of arc spraying equipment to heat, melt, atomize and spray by two charged wires(such as zinc, aluminum etc.) to form an anti-corrosion coating, plus with organic sealing coating for long time corrosion proof, the coating has obvious characteristics as:

It has a long corrosion proof lifetime which is more than 50 years and the coating will need no preventive maintenance in 30 years; 30 years later, only sealing paint needs to be brushed on the arc sprayed layer; without heavy-duty spraying, a preservative coating is realized for everlasting.

Arc sprayed coating and the metal substrate have excellent adhesion force (up to 10Mp), metal spraying layer is mechanical set and combined with micro metallurgy and metal matrix phase, under slight bending, impact or collision it can also ensure the coating will not fall off, not skin, firm combined, anti-corrosion for a long term, this can not be achieved by any other anti-corrosion coating on the surface

The principle of zinc spraying on steel structure is cathodic protection. In corrosive environment, even if the corrosion coating is partially damaged, it still has the effect of sacrificing itself to protect the steel matrix. (anode) coating and steel substrate (cathode) area ratio is not less than 1; while the ratio of zinc epoxy coating anode and cathode is <1, the protective effect and binding force is far lower than that of arc spraying coating.

2.0 Technical advantages of aluminum and zinc spraying on steel structure

Compared with flame spraying and arc spraying, due to the use of electricity instead of gas combustion, it greatly improves work efficiency and safety, especially the arc spraying equipment, technology has fully met the needs of bridge construction period and arc temperature is much higher than that of the flame, the adhesion is far greater than the flame spraying, therefore the coating quality can meet the needs of long-term preservation. Because of the high labor cost in the U.S.A, it makes the cost of using arc spraying for anticorrosion construction even lower than that of heavy duty anticorrosive paint. After decades of tests, it has been proved that spraying technology is the best method for long-term anti-corrosion of steel structure. This conclusion has been recognized by government departments and engineering circles in many countries in the world.

3.0 Construction technology of aluminum and zinc spraying corrosion protection for steel structure

General arc spraying equipment is composed of rectifier power supply, control device, spray gun, wire tray or wire feeding device, compressed air supply system, etc.. Wire trays and compressed air supply systems are the same as wire flame spraying. The process parameters of arc zinc and aluminum spraying have great relationship with the spraying material, and also depend on the equipment and production efficiency.

The application of aluminum and zinc on steel structure as long-term corrosion protection in China begins since 1990s. Metal spraying technology has been widely used in the field of metal spraying, and its application prospect is more extensive

4.0 Application of zinc and aluminum spraying anticorrosion on steel structure

It has been widely used in coal mines, railways, water conservancy, port, metallurgy, machinery, electricity, radio and television, medical, fire and other areas, such as Baoshan Steel Group and Majishan Port steel piles, Shanghai maglev track functional parts, the Three Gorges project, Wuhan Junshan Changjiang River bridge steel box girder and deck and other key state the construction project and the Qiandao Lake Nanpu Bridge, Changjiang River Huangbohe bridge, Guangzhou airport, Sanyuanli overpass, etc. The steel structure adopts arc spraying technique for corrosion protection, and achieved very good preservation effect. China has been fully capable of using arc spraying as long-lasting anti-corrosion technology to solve the national large-scale steel bridge corrosion protection problems

The heavy anti-corrosion technology of steel structure on the bridge develops until now, gradually there formed two major trends, one is the rapid development of the inorganic zinc epoxy coating for heavy anti-corrosion system base, two is relatively more mature in metal spray coating as the heavy anti-corrosion system of the substrate, the two systems are paid attention by all types of steel structure bridge because of its excellent anticorrosion performance and environmental adaptability. In the next few decades, the country will save a large number of steel corrosion protection costs, reduce environmental pollution, prolong the service life of steel bridges, and produce huge economic and social benefits

About Shanghai Liangshi IntelRobot:

Shanghai Liangshi IntelRobot Technology Corporation (Stock

code:837430 Accumulate richly and break forth vastly; innovate continuously ) We

provide surface treatment solution for global customers. Engaged more than twenty

years in the industry, Shanghai Liangshi is a professional manufacturing and automatic

system integration enterprise, specialized in researching, designing, manufacturing,

project installation and project consulting. We can provide our customers with:

1. We provide process system solution and process equipments of surface treatment shot blasting, thermal spraying, coating equipment.

2. We provide professional process system solution and process equipments of digital control automation and robot technology application.

3. We provide professional Integrated solution for pressure bearing system in fields of food dairy, biopharmaceutical, refrigerating, petrochemical, marine engineering, energy, paper-making, fabrics, etc.

4. We provide environment protection blasting and painting equipment: process solution and equipment of VOCs waste gas, waste water, dust, noise treatment system.

Leading products of our company are as follows:

Main business: designing, developing, production and sales of surface treatment project system integration.

Main products of six categories: automatic painting line, intelligent painting robot system, automatic shot blasting line, intelligent shot peening robot system, automatic thermal spraying system, energy saving and environment friendly painting equipment.

The products are mainly used in the fields: new materials, new energy, engineering machinery, automobile manufacturing, container, marine engineering, aerospace, port bridge, electrical appliances, environmental engineering, printing and papermaking machinery, medical machinery, textile machinery etc.

The surface engineering system integration produced by our company has the characteristics of intelligence and automation, and it can realize the automatic control of industrial production process, so it belongs to the automatic equipment. According to the "high-end equipment manufacturing industry" that defined by the“125 plan” , it mainly includes high value-added high-tech equipments that required by the transformation and upgrading of traditional industries and the development of strategic emerging industries, products of our company belongs to the high-end equipment, which is a strategic industry to provide technology and equipment for other sectors of the national economy

See more at:http://www.shliangshi.com or http://www.shliangshi.cn

Tel:021-51035200,68913886 Fax:021-68907128

China Service Phone:400-021-5767 Emergency

Phone:13901632687

E-mail:webmaster@shliangshi.com