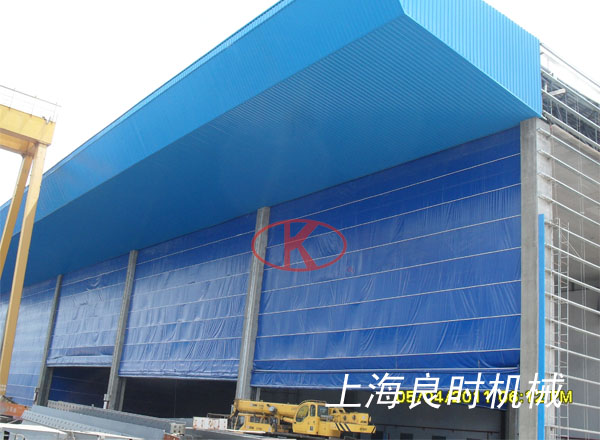

Ships segmented secondary blasting painting room

Secondary coating room (ship block painting room))

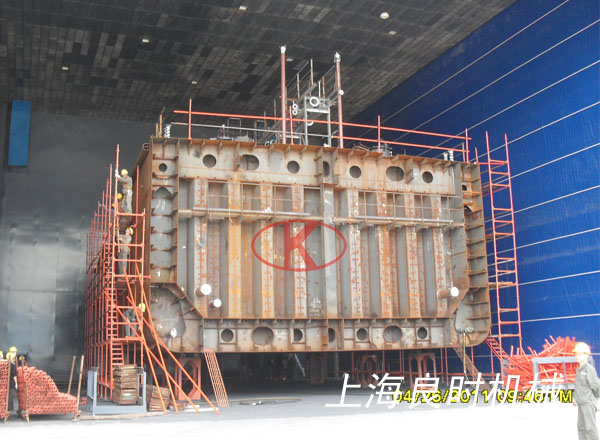

After the steel pre-processing can be handled within the range, they will be made as large as the giant hull section, these components needed in a room specially designed for secondary blasting shot, to achieve the perfect weld degree, and coated with a protective coating, in order to achieve corrosion resistance standard or platform hull construction.

Such a hull or platform segments typically weigh about 100 tons, even heavier. These components are fed into the corresponding sandblasting and painting rooms via special delivery device, accept blast cleaning internal and external surfaces of components. Using a vacuum recovery system will surface cleaned of residual pellets, pellets falling through a screw conveyor system will be collected, cleaned and recycled. Shanghai will provide a good time painting the entire room block painting ship systems engineering, systems integration equipment: sandblasting equipment, dust collector, cyclone, abrasive separator, belt conveyors, bucket elevators, vacuum sand, dehumidifiers, heaters, air compressors, flexible lift gates, organic solvent purification catalytic cracking unit, PLC centralized control system.

|

|

|

Guangdong, a shipyard PSPC ship section spray painting two three-coat paint sandblasting housing project |

A Guangzhou Shipyard block painting sandblasting |

Painting room and drying room system

Due to the size of a large part of the hull, so the painting process is carried out in a large painting room. This situation on the economic, environmental and health and safety spray equipment operator made a special request to run.

Shanghai good mechanical design and manufacture of ship coating spray booth is fully enclosed structure, indoor air inlet using the top, bottom side exhaust, exhaust gas purification filter through the mist after high-altitude emissions; paint systems using high-pressure airless spray equipment, either sprayed zinc-rich primer, paint can be sprayed conventional middle, paint, electrical control system uses PLC centralized real-time display control system. Curing Oven for workpiece paint, drying room temperature 25 ~ 35 ℃, can be an electric heater or heating fuel.

|

.jpg) |

|

Ships one block painting paint drying room |

Ship block painting spray booth |