In the power industry, shot peening can improve the performance of steam and gas turbines such as roulette, final blades, auxiliary parts and equipment, as well as reduce corrosion, fretting wear, fretting wear fatigue, fatigue and stress corrosion. Fatigue failure of parts such as cracking.

Shot peening is commonly used to prevent part failure on transmission components, gears and shafts. Recently, however, shot peening has been used more and more to increase the load-bearing capacity of key structures, such as shot peening of small-diameter stainless steel pipes on supercritical power stations; the test of spiral main-passing bevel gear overload benches in automobile axles Proved.

|

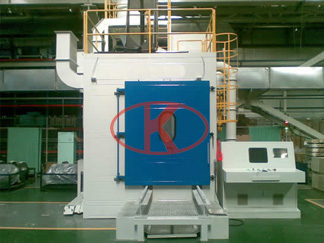

Shot peening machine for wind turbine speed increasing gear

|

|

Wind power bearing precision control automatic shot blasting equipment

|

|

As wind turbines get bigger and bigger, gearboxes are becoming more complex. The loss of equipment downtime due to gear failure becomes costly. After installation, the wind turbine is under the expected high load stress. High contact stresses on the gearbox and bearing surfaces at this time will create fine cracks, dents, scratches, and other unrecoverable wear.

Wind turbine equipment requires high gearboxes: small size, light weight, high reliability, long life and easy maintenance. Regardless of which gear is used, the tooth surface needs to be hardened and tempered to meet the needs of a special application environment such as a wind farm, in particular to greatly reduce the noise level when the fan is rotating. Hardening is to increase the hardness of the tooth surface, but it will cause the tooth surface material to be slightly misaligned, so it must be subjected to powerful shot peening.

|

|

Shanghai Liangshi designed and manufactured large-scale mechanical equipment such as wind power and marine equipment for the precision bearing automatic shot blasting equipment for a well-known bearing company in Dalian. In the wind power and shipbuilding industry, the anti-corrosion requirements of the slewing bearing are high, the table has high precision in processing requirements, and the workpiece diameter is large. For this reason, Shanghai Liangshi has developed automatic workpiece slewing mechanism + three-axis robot automatic blasting equipment. The automatic turning mechanism of the workpiece adopts the imported motor to drive the rotary table to perform the rotation, the variable speed of the rotary speed is adjustable, and the workpiece rotation is stable and reliable. For the turret bearing, the machining surface is multi-faceted and complicated. The three-axis manipulator is adopted. The X-axis displacement accuracy is not more than ±1mm, which fully meets the requirements of automatic shot peening. The Z-axis is similar to the X-axis. The linear bearing is used to make the operation more precise and stable. Digital control can be realized; the A-axis can realize 2-4 guns simultaneously swinging from -95 to +95°.

|

Shot peening machine for wind turbine blades

The fan turbine is under the action of vibration wind, that is, vibration stress, especially in the turbulent wind field climate environment. The rotating blade is forced to vibrate under the action of this periodic external force. This vibration is sometimes sudden, and the resonance causes cracks in a very short time, the vibration stress is extremely large, and the destructive force is strong, thereby generating cracks until fracture. In addition, the destructive force formed by the vibration of the blade itself and the vibration of the adjacent blade itself may also cause the surface crack of the blade to form and expand into a fracture. During the operation of the fan, if a high-speed object hits the blade, it is prone to cracks. Therefore, when designing the fan blades, the wind strength and power mode must be fully considered, and the most important is the metal anti-fatigue property of the rotating blades.

At present, the most economical and effective way to solve the metal fatigue problem of wind turbine blades is shot peening. By introducing a residual compressive stress on the surface of the blade, the destructive alternating tensile stress existing in the blade is offset or overcome, thereby increasing the fatigue strength of the blade, thereby ensuring and even prolonging the service life of the intended fan.

Small diameter (DN22mm~40mm) stainless steel tube inner wall shot peening equipment (left)

With the continuous construction of supercritical power stations and related industries, the requirements for the oxidation resistance of the inner wall of stainless steel pipes under the high temperature and high pressure of the heat exchangers and steam pipes are continuously improved. Therefore, the requirements for the production process equipment of the stainless steel pipes are becoming more advanced. For example, 18-8 series stainless steel pipes such as SUS321HTB used in boilers, superheaters and reheaters in thermal power generation, due to long-term high temperature (above 540 °C) high pressure (greater than 25 MPa) water vapor, the inner surface is more prone to iron oxide scale. It is easier to peel off, causing blockage of pipes and damage to equipment. Many years of research by experts at home and abroad have shown that the inner wall of stainless steel pipe can be improved by shot peening to improve its oxidation resistance. Experiments show that after the inner wall of stainless steel pipe is changed by shot peening to change the surface microstructure, various elements in the process of use (especially It is a significant change in the Cr) enrichment layer, which greatly improves its oxidation resistance, so that the thickness of the oxide layer is 0.07% to 1.7% without shot peening, and the oxide layer has no peeling phenomenon, and the shot peening is good. effect. Therefore, at present, such special stainless steel pipe manufacturers in China require the use of such small-diameter stainless steel pipe inner wall shot peening equipment to improve the anti-oxidation ability of the inner wall of the stainless steel pipe and at the same time achieve the effect of hardening the inner wall of the pipe.