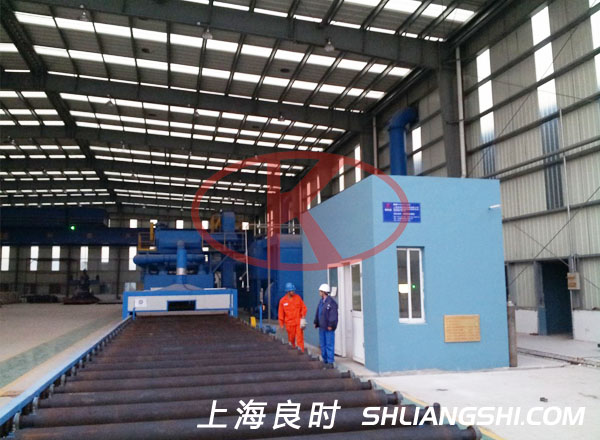

Production line for shot blasting of thin plate and steel plate

.jpg)

Shanghai Liangshi Intelligent specializes in providing system equipment such as primary sanding line for container thin plates, automatic secondary sanding line for inner and outer containers, container beauty line, and container completion line.

Steel plate shot blasting pretreatment line for equipment logistics industry:

The shot blasting pre-treatment line utilizes the centrifugal force generated by the impeller of the shot blasting machine during high-speed rotation to shoot the abrasive at a high linear speed onto the treated steel surface, generating a striking and grinding effect, removing the oxide skin and rust on the steel surface, exposing the metal's true color and presenting a certain roughness on the steel surface, in order to facilitate the adhesion of the coating.

The efficiency of shot blasting treatment is high, and it can be carried out under closed conditions, equipped with a dust absorption device to avoid polluting the environment. In addition, equipped with an automatic painting device, it can achieve the integration of rust removal and painting (temporary maintenance) workshop primer and automatic flow process.

Suitable for large quantities of metal plates, metal sheets, and marine steel.

Steel plate/profile steel shot blasting pretreatment line

The steel shot blasting pretreatment pipeline is abbreviated as the steel pretreatment pipeline. Generally, there are two types: one is the steel plate pretreatment pipeline, and the other is the section steel pretreatment pipeline. The working principles of both are consistent, but due to the relatively complex surface of the profile steel, the placement of the peening head of the shot blasting machine should have a specific angle, and the width of the profile steel is significantly smaller than the width of the steel plate. Therefore, the number of peening heads in the profile steel assembly line is smaller than that in the steel plate assembly line, and the width of the roller table is also smaller than the width of the roller table in the steel plate assembly line.

Shot blasting spray painting drying pretreatment line:

Shot blasting treatment uses the centrifugal force generated by the impeller of the shot blasting machine during high-speed rotation to shoot the abrasive at a high linear speed onto the treated steel surface, generating a striking and grinding effect, removing the oxide skin and rust on the steel surface, exposing the metal color and presenting a certain roughness on the steel surface, in order to facilitate the adhesion of the coating.

The efficiency of shot blasting treatment is high, and it can be carried out under closed conditions, equipped with a dust absorption device to avoid polluting the environment. In addition, equipped with an automatic painting device, it can achieve the integration of rust removal and painting (temporary maintenance) workshop primer and automatic flow process.

Shanghai Liangshi has successively provided the design, manufacturing, and installation of steel plate pretreatment lines, coating equipment, and coating rooms for dozens of domestic shipyards. Our customers include COSCO Shipping, Dalian Shipbuilding Heavy Industry, Jiangnan Shipyard, Hudong Zhonghua Shipyard, Jiaolong Heavy Industry, and others.

|

Production Line for Shot Blasting Pretreatment of Steel Plate for Wind Power Tower

|

.jpg)

Marine steel plate shot blasting, painting, drying and pretreatment line

|

|

Energy Offshore Equipment Steel Plate Shot Blasting Painting Drying Pretreatment Line

|

.jpg)

Pre-treatment line for shot blasting, painting, drying and drying of container steel sheets

|