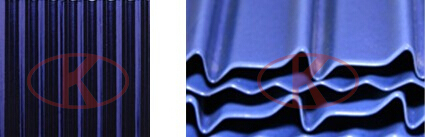

Shanghai Liangshi professional provides you with power plant equipment GGH enamel enamel painted the enameling line of heat transfer components, air preheater pipe coating production line of corrugated board production line, painted enamel-lined. Enamels are often used for regeneration air-air & gas-gas factories used to control the use of heat exchanger parts (enameled corrugated plate/enamel heat pipe) provide anti-corrosion protection, such as desulphurization of flue gas (FGD) and in large scale fossil fuel-flow powder plant at the end of SCR plant.

Another reason to choose enamel is that it is easy to clean and the surface of the enamel spray fireproofing.

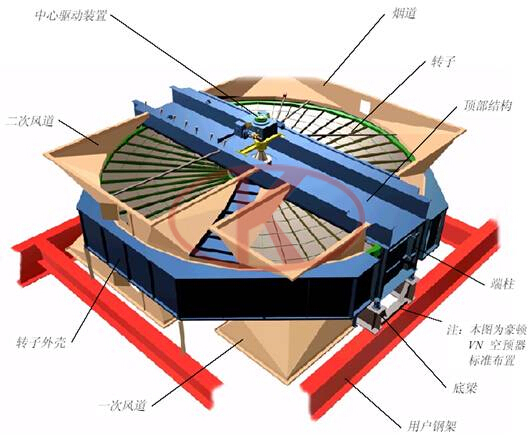

Thermal power plant air preheater GGH heat transfer components (direct channel large corrugated board) pre-treatment production line of enamel drying and sintering system equipment specializing in the design and manufacturing services.

Air preheater appears following problems, consider using ceramic heat exchanger element:

○Low temperature corrosion serious ○Ash fouling serious ○High rate of air leakage

Heat exchanger element characteristics:

•superior corrosion resistance, strong acid and alkali.

•The surface is smooth, not easy to fouling, reduce congestion, easier to clean.

•Can reduce exhaust gas temperature, improve operational efficiency.

•Superior wear resistance, erosion resistance capacity.

Power plant air preheater heat exchanger element enamelling production line |

Power plant flue gas desulfurization system enamel heat pipe enamelling production line |

Air preheater heat exchanger element enamel professional design and manufacture of corrugated board and enamelling pre-treatment production line drying sintering process and system equipment |

Air preheater and flue gas heat exchanger with enamel coating keeps out the production of heat exchange components mainly for the wet dipping enamelling processes, wet electrostatic spraying , dry electrostatic spraying process.

Coal-fired power plant emissions of air pollutants can reach natural gas generator set emission standards".From March this year, Beijing, Tianjin and other countries for the implementation of special emission limits areas, coastal areas to implement " Near-zero emissions "requirements,"Near-zero emissions"almost overnight it became the target of new thermal power plant.However,"Near-zero emissions"For environmental's performance optimization, structural design, system upgrade puts forward new requirements, experienced a prolonged, large-scale, explosive growth of environmental equipment industry is starting to look real on equipment upgrades and technological level.

In fact, what is "Near-zero emissions ","Zero-emissions"and "Ultra low emissions"concepts, there is no clear standard. but usually gas-fired generation emissions levels as the reference standard in industry.However, from around the first half of this year, released by the City Government's new round of desulfurization and denitrification and dedusting of policy files can be seen ,"Near-zero emissions"Refers to gas turbine set emission limit values, namely for carbon concentration less than 5 mg/m³, the concentration of sulphur dioxide emissions no greater than 35 mg/m³, nitrogen oxides emissions concentration not greater than 50 mg/m³.

June 19 this year, Zhejiang Province Development and Reform Commission issued the Zhejiang Jiaxing Power Plant Unit 8 can achieve near-zero emissions of news. This is our first set of one million kilowatts production unit flue gas of coal-fired ultra-low emission device, the 8th unit uses a "multi-pollutant removal efficiency synergistic integration technology," the level of smoke emission of major pollutants at or better than gas emission standards unit, blew our thermal power units "Near zero emissions" build number.

Shortly thereafter,ShenHua GuoHua ZhouShan power Plant's unit 4th official transfer of production,this unit is the first new "Near-zero emissiona" coal-fired generating units. The unit synchronized supporting the construction of a highly efficient flue gas deNOx facility (low burner +SCR by catalytic reduction of nitrogen),using high efficiency electrostatic precipitator (high frequency power supply, rotate the electrode), water from flue gas desulfurization unit.

From the above case is not difficult to find, and "Near-zero emissions" for environmental protection equipment and even entire power system devices will bring revolutionary changes."ear-zero emissions"It not only requires power plant in desulphurization and denitrification and dedusting devices to technical innovation and upgrading, but also for coal elemental composition, induced draft fan for boiler selection, configuration, performance optimization and adaptation of catalysts or even entire power generation system designs were put forward new requirements.In short, the "near zero emissions" is not only the requirements of desulfurization and denitration equipment mention other environmental efficiency retrofits, but also opened a new model of the entire power system design.

From the dust removal renovation of desulfuration and denitrification to "Near-zero emissions" target put forward, in essence, is the inevitable result of the development of coal-fired power plant in China in the course of, Since China is a big country of coal-fired power generation, and coal-fired power structure dominated in a short time will not change, then in order to achieve clean and efficient power generation, reduce air pollution emissions,"Near-zero emissions" would be a good choice.However, the particularity of coal and ash letting the task becomes even more difficult, "Near-zero emissions"i n most areas still face greater difficulties.

In Zhejiang, Shanghai, Guangdong and other coastal areas of eastern China, "coal-fired power plant emissions of air pollutants to reach natural gas generator set emission standards" has become possible.

With China's power generation equipment and environmental equipment technology continues to improve,"Near-zero emissions" seems to have become an industry consensus and popularized by reference, and the environmental protection industry to do work the heart sank down, change the past to pursue"Bigger Faster"concept ,turned to a high level, high efficiency environmental protection equipment development and research, for coal-fired power plants "Near-zero emissions" to lay the foundation.