Shanghai Liangshi (Liangshi TM) provides high-performance robotic automatic sandblasting and spraying equipment for automotive manufacturing, rail vehicles, casting machinery, wind energy and energy industries, various steel structure manufacturing, aviation, and other fields. Through innovative sandblasting and spraying system solutions, using efficient, reliable, flexible, and safe sandblasting and spraying robot systems, we provide customers with excellent product surface treatment and improve product added value.

Shanghai Liangshi (Liangshi TM) provides high-performance robotic automatic sandblasting and spraying equipment for automotive manufacturing, rail vehicles, casting machinery, wind energy and energy industries, various steel structure manufacturing, aviation, and other fields. Through innovative sandblasting and spraying system solutions, using efficient, reliable, flexible, and safe sandblasting and spraying robot systems, we provide customers with excellent product surface treatment and improve product added value.

The main advantages of Liangshi spraying robot:

Large flexibility: large working range, with the possibility of upgrading; Spraying of inner and outer surfaces can be achieved; It can realize the mixed line production of multiple types of vehicles, such as sedans, station wagons, pickup trucks, and other vehicle bodies.

Improve spraying quality and material utilization: accurate profiling spraying trajectory, improve the uniformity of coating film and other appearance spraying quality; Reduce the amount of overspray and cleaning solvent, and improve material utilization.

Easy to operate and maintain: Can be programmed offline, greatly reducing on-site debugging time; Pluggable structure and modular design enable rapid installation and replacement of components, greatly reducing maintenance time; The maintenance accessibility of all components is good, facilitating maintenance.

High equipment utilization: The utilization rate of reciprocating automatic spraying machines is generally only 40%~60%, while the utilization rate of spraying robots can reach 90%~95%.

|

.jpg)

Liangshi Aircraft Parts Robot Spraying Room

|

.jpg)

Liangshi Aircraft Parts Painting Robot

|

|

.png)

Automatic painting of outer wall of wind power tower by robot

|

.jpg)

Automatic Spraying Robot for Wind Power Bearing

|

|

Robot gluing system for high-speed railway pantograph

|

Robot Spraying System for Automotive Shock Absorbers

|

|

Robot painting system for wheel hub

|

.jpg)

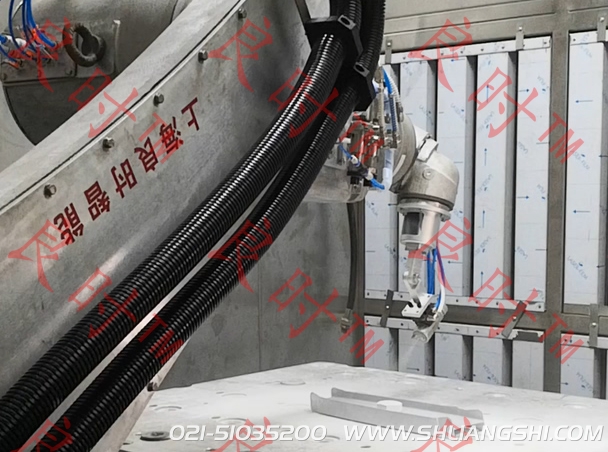

Robot assisted automatic sandblasting and zinc spraying system equipment

|