High speed industry has a high requirement on the hardness, wear resistance and anti-fatigue, and can keep a good performance under high alternate load.

Digital control shot peening application:

Fatigue-by implanting a certain extrusion pressure stress, it can control the production and development of the fatigue split

Abrasive wear- it will result in the fatigue destroy, shot peening can improve the surface contact and produce extrusion pressure on the surface, which will reduce the possibility of abrasive wear.

Stress corrosion split- reduce the surface stretch stress or make it reduce below the limit point can remove the production of stress corrosion split.

Most of the locomotive industry uses the metal material, including motor (crank shaft, connecting rod), suspended traction structure, transmission parts (gear\ gear shaft), all adopt the shot peening technology to meet the performance specification of material

|

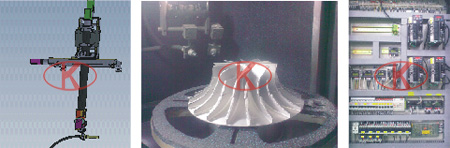

CNC4 axis linkage digital control shot peening equipment (compressor blade shot blaster)

4-axis linkage digital control shot blaster is designed and made by Shanghai Liangshi Machinery for a locomotive manufacturing company, the good performance of equipment is well received by the user, this 4-axis linkage digital control shot peening machine applies to the shot peening for compressor blade work piece.

|

|

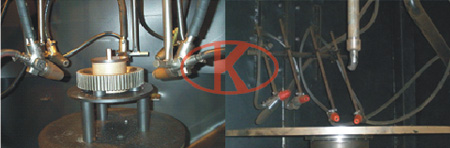

Digital shot peening equipment for Dalian locomotive gear

The shot peening for gear and connecting rod is a common application. Gear of any dimension or design can be improved of the deflection fatigue resistant performance.

|

The gear will be shot blasted after the surface is quenched. The increasing hardness will cause pressure stress of the same ratio. It depends on the parameters of carburizing treatment and shot peening, the maximum residual stress of gear after the blasting will fall between 170-230 ksi (1170-1600MPa). Harder shot will be used in the shot peening of carburizing gear.

By hammer impact, a pressure stress will be induced in the boring mill, thus forming fatigue resistance on the gear, it is the best way at present. Making the pit by shot peening finishing can diffuse the contact load and reduce the contact stress therefore.

|

|