Arc is which in the gas medium between two electrodes intense discharge phenomenon,when discharging , arc area produce strong light and heat .

Image: Single stream center atomized transport mode arc melting shot spray principle

ARC melting shot spraying is the use of two continuous conveying wire as consumable electrode , arc that between two pieces of conductive wire used as a heat source to melt itself,and then send the molten metal atomization to the product surface with high speed to form a coating .

To preserve arc stability burning in the two ends of wire , on the one hand you need to plus the the airflow then make the molten metal away from the end of metal , on the other hand need to establishing the appropriate balance with arc voltage ,arc current and wire speed.

Image: Dual-stream atomized transmission arc melting shot spray principle

This pattern can better controll the particle size of jets , and because two different gas sources can be used, particularly the addition of inert gases used, creates conditions for the control of special coating.

In the older generation experts of industry for their support and help, Shanghai Liangshi making full use of modern control technology,freedom advanced manufacturing equipment and technologies, and constantly improve and develop marketable terminal products requires arc melting shot and spray equipment, becoming the industry leader.

From early arc melting shot equipment host LSQD8D series developed to LSARC series and LSARCE series, melting shot spray gun from the eighth LSQD8 series developed to LSQD8S series, LSQD9 series, LSQD10 series and LSARC2E atomized series, to meet the different coatings's melt spray requirements. Control system according to different conditions configured, to meet the requirements of operational use.

Arc melting shot host

★LSQD8D series arc melting shot machine

Power generator with silicon rectifier mode ,has better dynamic characteristics and external characteristics, providing DC for melting shot wire then form arc,arc energy is converted to heat release, meet melting of the wire.

Divided by the rated output current of the unit, commonly used LSQD8D250, LSQD8D300, LSQD8D400 units, special purpose can be configured to LSQD8D500, LSQD8D600 and LSQD8D1000.

Mainly used for large areas of steel structure corrosion and wear protection, processing errors or worn equipment surface repair and preparation of special coating and so on.

According to different production needs, supporting different types of spray guns (pull-type series or push-type series+ wire feeder system)and plus a variety of control system, which can satisfy different (push or pull manual, online Automation) application requirements.

Right:LSQD8D series arc melting shot machine

Table:Model LSQD8D400 / 300/250 arc spraying power parameters and characteristics

| Serial number |

Content of the project |

Parameters |

1 |

Input power |

3 phase AC380V, 50Hz |

2 |

Rated input power |

18.8KVA、13.2KVA、7.5KVA |

3 |

Rated current |

400A、300A、250A |

4 |

No-load output voltage |

21~45V、18~42V、14~36V |

5 |

Load rate |

60% |

6 |

Voltage regulator series |

Coarse and fine adjustment of each 3 files, a total of nine stalls |

7 |

Dimensions |

600×460×850 |

8 |

Weight |

≈190kg、170kg、145kg |

9 |

Insulation class |

E |

★★ LSARC series arc melting shot machine

As an upgrade type of LSQD8D series,it has the following characteristics:

1、Unique Gas Inspection Program: Panel set up the green button seized gas switch, after the host is powered press the switch, it can check whether there is gas discharge from spray gun , and can view the gas pressure in the ventilation state, if the barometer pressure is too low to display (eg 0.50MPa), is not recommended for spraying operations, to avoid short-circuiting wire or atomization bad;

2、Safety interfaces: International closed-end piles were used to connect the output cables, avoiding external short circuits may cause significant harm to the host system;

3、Newly developed system rectifier steady flow uniformly atomized particles, uniform appearance coating quality, indicating that our equipment reached the international advanced level!

4、The system controls the temperature of the arc zone,reduce the amount of the exhaust gas as well as the metal vaporizing,greatly reduce the vaporized metal and the exhaust gas may effects on the environment and the operator .

Left: LSARC series arc melting shot machine

Divided by the rated output current of the unit, commonly used LSARC250, LSARC300, LSARC400 units, special purpose can be configured to LSARC500, LSARC600 and LSARC1000.

Table:

Model LSARC400 / 300 / 250 arc spraying power parameters and characteristics

| Serial number |

Content of the project |

Parameters |

1 |

Input power |

3 phase AC380V, 50Hz |

2 |

Rated input power |

18.8KVA、13.2KVA、7.5KVA |

3 |

Rated current |

400A、300A、250A |

4 |

No-load output voltage |

21~45V、18~42V、14~36V |

5 |

Load rate |

60% |

6 |

Voltage regulator series |

Coarse and fine adjustment of each 3 files, a total of nine stalls |

7 |

Dimensions |

750×500×960 |

8 |

Weight |

≈195kg、175kg、150kg |

9 |

Insulation class |

E |

Another LSARC-S series arc melting shot machine

Which host designed for use with dual-stream atomization spray gun, for users who require special coating is the best choice.

Special features spray coating can be close to the spray welding effect and subsequent processing is relatively easy. In the re-manufacturing, the use of this type of device can greatly simplify the process and get the same excellent remanufactured products.

Specially designed dual-stream system input and output, for use with dual-stream atomization gun support. Using the latest silicon rectifier power to the host system, with excellent dynamic characteristics and external characteristics.

Commonly used are LSARC250S, LSARC300S, LSARC400S unit, special applications can be configured to LSARC500S, LSARC600S and LSARC1000S.

Left:LSARC-S series arc melting shot machine

★★★LSARCE series arc melting shot machine

At present the most advanced arc melting shot host, with double pneumatic control output, combined with different spray gun, industrial control systems, to control the thickness of the coating and surface roughness.

Currently, with equipment with micro-channel aluminum flat pipe online spraying 1μm thickness coating applications and control special coatings's surface roughness technology shows excellent performance, reaches the international advanced level.

Rated output current of the host 250A—1000A, tailored according to user requirements.

Image:LSARCE series arc melting shot machine

Melting shot spray gun

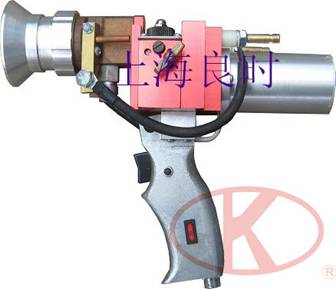

★ LSQD8 series arc melting shot spray gun

Left:LSQD8LA series arc melting shot spray gun

General conditions of use melting shot gun, can be used manually or by machine with DC-motor as the wire feed drive motor.

The gun provides regular-speed and high-speed modes.

Right:LSQD8LA-N melting shot spray gun which especially designed for inside hole spraying and special parts spraying

Melting shot spray gun especially designed for inside hole or trench corner needs painting,commonly used manual work mode, using DC power as wire feed motor.

LSQD8 series melting shot spray gun's performance and related technical data

Serial number |

Project |

Data and instructions |

Model |

Common wire |

Air Cap |

Maximum wire feed speed |

1 |

LSQD8LA pull-type melting shot spray gun |

Suggestions

φ1.6-2.0

A variety of materials |

φ7-8 |

About 7M/min |

LSQD8LA-S dual-stream melting shot spray gun |

2 |

LSQD8LA-G high-speed pull-type melting shot spray gun |

About 9M/min |

LSQD8LA-GS dual-stream high-speed melting shot spray gun |

3 |

LSQD8LA-N pull-type melting shot inner bore spray gun |

About7M/min |

Comprehensive performance |

4 |

Power source |

0-24V DC |

5 |

Speed control mode |

Stepless |

6 |

Weight |

About 2.95Kg |

7 |

Dimensions |

About 340×300×100 |

8 |

Wire Feed |

≥8.0Kg |

Due to LSQD8LA-S and LSQD8LA-GS provides dual-stream then atomized pattern, with LSARC-S series or LSARCE series arc melting shot machine, you can use two different atomizing air transportation,provide conditions for special coating protection needs.

★★ LSQD9 series melting shot spray gun

Left:LSQD9 series melting shot spray gun

Designed specifically for smaller format materials manually or online job ,the transmission system using aluminum alloy casing, different from LSQD8 series of plastic gear box, long life, less wearing parts.Widely used in welded steel pipe,online zinc patching and steel mills online printing ,iron and other industries,generally using a DC motor as the wire feed motor power can also provide servo and PLC program control mode according to user requirements.

Due to suitable for the small size material,the smaller atomization zone control,you can get a narrower spray rate,meanwhile, advanced airflow control technology enables get smaller and uniform atomized particles ,coating delicate and beautiful.

LSQD9 series melting shot spray gun's performance and related technical data:

| Serial number |

Project |

Data and instructions |

Model |

Common wire |

Air cap |

Maximum wire feed speed度 |

1 |

LSQD9LA pull-type melting shot spray gun |

φ1.0-1.6 |

φ5-7 |

About 3M/min |

2 |

LSQD9LA-G high-speed pull-type melting shot spray gun |

About 6M/min |

Comprehensive performance |

3 |

Power source |

0-24V DC |

4 |

Speed control mode |

Stepless |

5 |

Weight |

About 3.40Kg |

6 |

Dimensions |

About 300×300×140 |

7 |

Wire Feed |

≥8.0Kg |

Low speed wire feed and wire size smaller, for a host of external characteristic and dynamic characteristic of requirements will increase general support in LSARC250 to use the spray gun, widely Φ1.0-1.6 rolled zinc coating of the aluminum spray or Φ1.2-1.6, you can get high quality coating.

★★★ LSQD10 series melting shot spray gun

Image:LSQD10 series calculation arc melting shot spray gun

LSQD10 series melting shot spray gunn's performance and related technical data

| Serial number |

Project |

Data and instructions |

Model |

Common wire |

Air cap |

Maximum wire feed speed |

1 |

LSQD10LA pull-type melting shot spray gun |

φ1.2-2.0

A variety of materials |

φ5-8 |

About 7M/min |

LSQD10LA-S dual-stream melting shot gun |

2 |

LSQD10SF meticulous pull-type melting shot spray gun |

About 10M/min |

LSQD10SF-S dual-stream meticulous melting shot gun |

Comprehensive performance |

3 |

Power source |

LSQD10LA:DC 0-24V 60W |

LSQD10SF:Servo-drive |

4 |

Speed control mode |

Stepless |

5 |

Weight |

About 5.0Kg |

6 |

Dimensions |

About 380×200×140 |

7 |

Wire Feed |

≥10.0Kg |

Designed specifically for online spraying jobs , drive system made in aluminum alloy box body, as distinguished from basic plastic-free, long life, very few wearing parts.

Generally applicable to LSARC300, LSARC400 to use, widely applicable Φ1.2-2.0 specifications of various wire coating, you can get high quality coatings.

Widely used in various industries, motor or servo DC motor with PLC control system for online automatic jobs.

Because LSQD10LA-S and LSQD10SF-S provides dual airflow atomized mode configuration, you can use two different atomizing air transport, with LSARC-S series and LSARCE series arc melting transmitter used for special coating to protect need to provide the conditions.

Widely used in mid-microchannel aluminum flat tubes online sprayed zinc operations, capacitors surface spray zinc and ceramic capacitors surface sprayed aluminum and other industries, the use of a DC motor or servo motor control system with PLC online auto job.

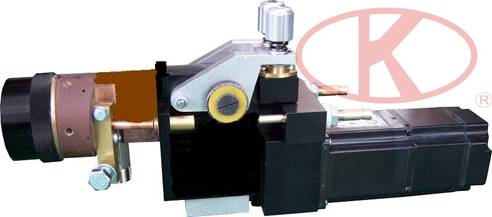

★★★★LSARC2E series melting shot spray gun

Image:LSARC2E series arc melting shot spray gun

Having a central gas atomization and circumferential function then atomized spray gun, widely used in areas with a special coating.Basic support for LSARC S-series or E-series hosts to oxidation control of particle size and material of the coating rate purposes.

Currently, this type of gun is widely used in high-grade microchannel aluminum flat pipe spraying zinc operations, to prepare the 1 μ m thickness of coating,full supporting systems in the international leading level.

2.3 Push-type and push-pull combination type arc melting shot spray equipment configuration

Traditional arc melting shot equipment there are two methods for wire feeding: front-pull and push-back , spraying methods derived from what we call pull-type arc spraying and push-type arc spraying.

| Compare |

Front-pull wire feed |

Push-back wire feed |

| Features |

Wire feeding power on the gun body |

Wire feeding power separate from the gun body |

| Advantages |

1. Compact structure;

2. Wire Feed stability, good atomization effect;

3. Spray gun can be far from power, operating flexibility |

Gun basically responsible for the atomizing function, the structure is relatively simple, relatively light weight |

| Shortcoming |

1. After the gun is connected with the overall weight of the trachea and the cable is relatively heavier, hard to operate;

2. Transmitting power is relatively small |

1. Due to the Wire feeding power back, short distance between wire feeder and gun, generally not more than 2 metres, job is not flexible, suitable for large flat workpieces operation;

2. Not suitable for using a soft wire |

| Combination |

Push-pull dual-use |

Through a combination of installation of our equipment, it can be realized and integrated into control systems suitable for push, pull and push-pull the three series of arc spraying requirements:

Push-back mode device main configuration:

1. Arc melting shot electric source

LSARC series arc melting shot machine, such as LSARC400, LSARC500, LSARC600 and LSARC1000 are available as places where different job matching.

2.Model LSB10-KT wire feeder

Parameters Table:

| Contents |

Basic parameters |

Weight |

About 18kg |

Dimensions |

580×360×280(mm) |

Thrust, speed |

Thrust>8Kg、speed 0.7-7M/min |

Control |

DC24V steplessly adjustable |

Motor output power |

65W |

Push-type job requirements for wire:

Zinc wire: General & ge; & phi; 3-5 specifications of materials ,commonly used specifications for & phi; 3 or & phi; 3.17;

Aluminum wire: General≥φ2-3specifications of materials,commonly used specifications forφ2.3 orφ3;

Other: stainless steel, carbon steel, generalφ2specifications of materials;

Model 3.LSXTQ1 push-type melting shot spray gun

Push-type melting shot spray gun technical parameters:

| Content |

Basic parameters |

| Dimensions |

120×200×90(mm) |

| Weight |

About 1.30kg |

| Wire diameter |

Φ2.0≤General use of conventional≤Φ3.0mm |