Sandblasting/shot peening robots system

Using robots to replace manual blasting operations, with automation, high efficiency, stable operation, high precision blasting, and safety. In the hard and dangerous manual sandblasting gradually being replaced by automatic blasting technology today, robots sandblasting the clean-up program has become a trend.

◆Automation: After entering the workpiece code robot can automatically identify a variety of artifacts and automatically complete the blasting operations, disposable completely covered, without human assistance.

◆High efficiency: blast-cleaning robots can work tirelessly, and it is a lot of times higher than conventional sandblasting by hand. creating a sharp lead in the efficiency of blast-cleaning robot.

◆Stable: the robot using programming control, stable operation. No manual sandblasting tired, misjudgment, emotional instability. The robot has a protection device, the case of non-normal collision will automatically stop reset, system alarms.

◆Sandblasting high precision: robots run with high sensitivity, stable operation, repeat the path accuracy up to 0.1mm, far from artificial can. After sandblasting the surface quality of the workpiece is ideal, has very good cleanliness and roughness can be painted directly, or for additional processing.Appropriate blasting pressure, nozzle piece suitable distance away from the blast, and accurate blasting angle will directly affect the roughness and cleanliness.Blasting robot uses the most suitable surface requirements pellets and air pressure. Distance and angle of the nozzle can be continuously adjusted to ensure high standards of customer quality requirements.

◆Security: manual sand blasting is very hard and dangerous and harmful to health. The operator should bear the noise, dust intrusion, the body is prone to overwork.If dealing with large pieces of equipment, you also need to use a ladder and staging work has become very dangerous. Operators need to wear heavy, suffocating shields to avoid pellets's violations which fly speed 200 m/sec.Artificial blasting accidents and injuries often occur, and therefore production is often delayed.Willing to engage in such a laborious and dangerous work fewer and fewer people, mobility is very frequent.Blasting robots will be able to solve all the problems mentioned above.The operator manually operate the robot, sitting in air-conditioned cabin of humanization operation, by a joystick to control the robot.When the robot automatically clean the workpiece, the operator just need to in the control room which is outside the blasting room and monitor blasting robots .

Right: bridge-blasting robot system

|

Automatic Robot sandblasting

|

|

Water treatment equipment automatic robot sandblasting system

|

|

Programmable microprocessor control system, six-dimensional motion of robot-assisted execution spray gun; rail trolley conveyor systems, automatic flexible lifting doors; collection of air separation, recycling of abrasive, dust in one; environmental efficiency between manufacturers and users have built remote monitoring and diagnostic systems. |

|

The automatic sandblasting equipment is highly efficient, reliable, flexible, secure, blasting robots, equipped with automatically rotary table, Rotary variable frequency adjustable speed, smooth and reliable workpiece rotation. To provide customers with excellent surface quality and higher value-added products. |

Blasting/ shot peening robot system applications

|

Aircraft landing gear of CNC peening robot system

|

|

Robot peening (blind hole miniature spear)

|

|

Wall-mounted robot blasting system

|

|

ABB peening robot system

|

|

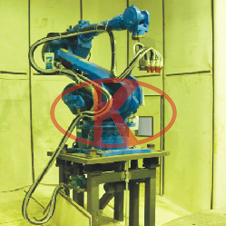

Yaskawa blasting robot system

|

|

FANUC peeing robot system

|

|

Automatic wall-mounted robot sandblasting room system

|

|

Rail locomotive robot sandblasting room systems live

|