Water sandblasting machine/environmentally friendly water sandblasting machine/dustless water mist sandblasting machine

Liangshi Intelligent (stock code: 837430) environmentally friendly dust-free water mist sandblasting machine is safe, high-quality, efficient, energy-saving, environmentally friendly, and intelligent. Quick cleaning of coatings and rusted surfaces, designed specifically for environmental protection, energy conservation, and emission reduction operations, almost suitable for any metal or stone surface. Suitable for a variety of abrasives, it is more environmentally friendly than dry sandblasting, more flexible than shot blasting, and has lower costs than high-pressure water jet.

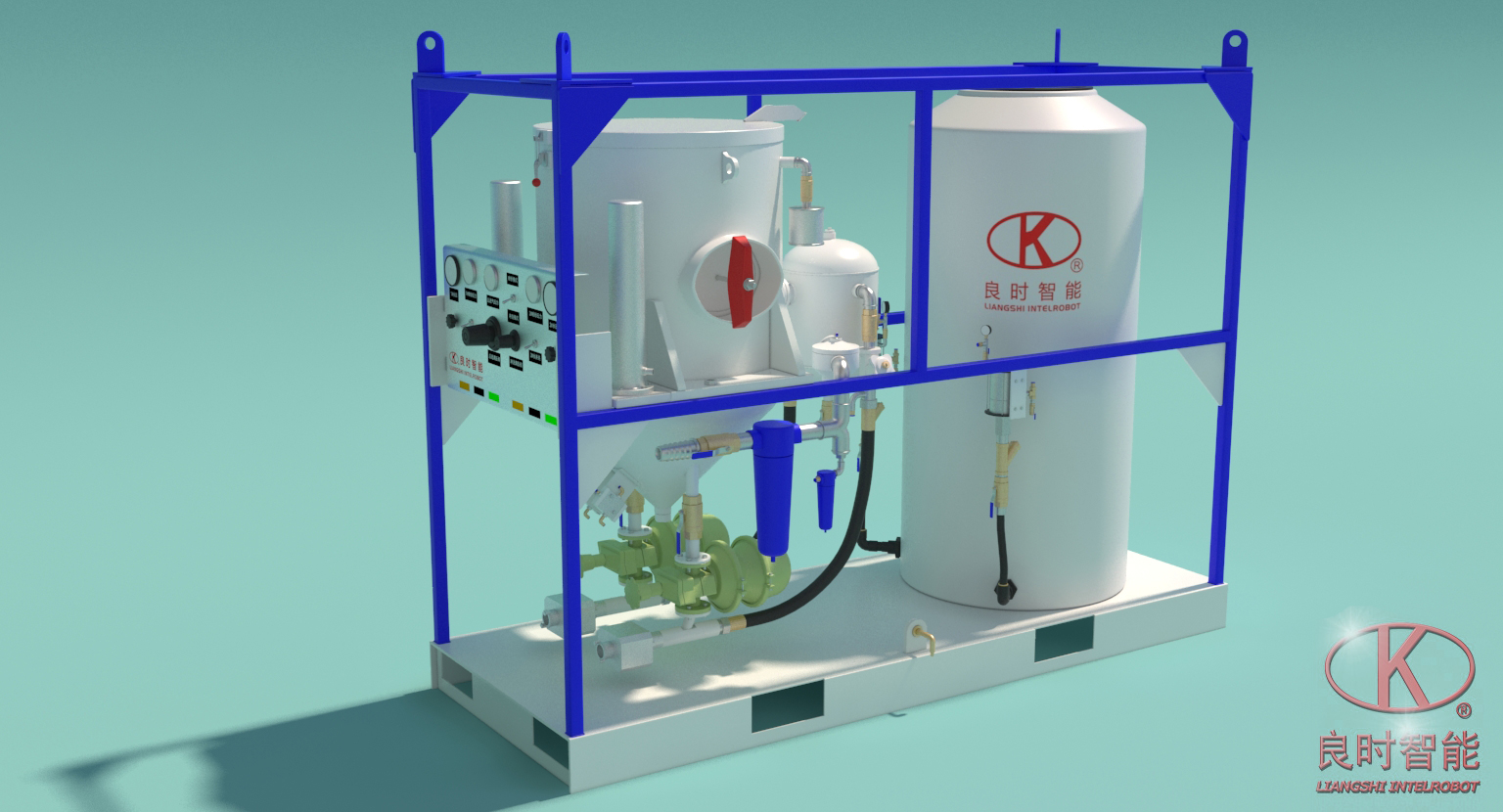

3D diagram of environmentally friendly water sandblasting machine/dust-free water mist sandblasting machine

Main parameter configuration of environmentally friendly dust-free water mist sandblasting machine:

1. Maximum sandblasting pressure: 12bar

2. Applicable working pressure for coating cleaning: ≥ 6bar

3. Sand blasting tank capacity: 100L

4. Maximum air volume: 500CFM (14 cubic meters)

5. Applicable abrasive: 12-150 mesh

6. Water sand hose: 10 meters or customized

7. Overall dimensions: 1100 * 850 * 1175mm (L * W * H)

8. Equipment weight: 320kg

Three working modes can be switched freely: 1. Water sand spraying 2. Clear water flushing 3. Air blowing

Environmentally friendly dust-free water mist sandblasting machine is superior to dry sandblasting:

1. Significant reduction in medium consumption

2. Dust reduction rate up to 90%~98%

3. Save costs on cleaning and disposing of waste

4. It can replace dry sandblasting in terms of speed and spraying force

5. Adjustable injection pressure

6. Suitable for almost any metal or stone surface

7. It will not damage the substrate and can work in rainy and high humidity environments

Features of environmentally friendly dust-free water mist sandblasting machine:

1. Effectively reduce the diffusion of sand and dust during open sandblasting operations.

Compared to traditional water sand mixed sandblasting machines, the water consumption is reduced by more than 60%.

3. The entire machine adopts pneumatic control, which is safe and explosion-proof.

4. Abrasives have a wide range of applicability and work efficiency comparable to ordinary dry sandblasting machines.

|

Nozzle diameter

(mm)

|

Air volume

(m3/min)

|

Sand consumption

(kg/h)

|

water consumption

(L/h)

|

Scanning area

(m2/h)

|

|

8 |

3.92 |

400 |

40-80 |

10.7 |

|

9 |

4.96 |

506 |

40-80 |

13.6 |

|

10 |

6.1 |

622 |

40-80 |

16.7 |

|

11 |

7.4 |

755 |

40-80 |

20.2 |

|

12 |

8.8 |

900 |

80-120 |

24.1 |

|

13 |

10.3 |

1050 |

80-120 |

28.2 |

|

14 |

12.0 |

1220 |

80-120 |

32.7 |

|

15 |

13.8 |

1400 |

80-120 |

37.5 |

Advantages of environmentally friendly dust-free water mist sandblasting machine:

Adding water and sand to the sandblasting machine will suppress most of the dust! In order to meet environmental requirements.

When sandblasting, water and sand come into contact with the surface of the steel structure at the same time, and the sand material will not produce sparks when it impacts the surface of the steel structure.

3. The effect is the same as dry sandblasting, and can reach Sa2.5-3 levels

4. Add anti rust agent to the tank, and the anti rust powder can be kept outdoors for one week

5. Easy to operate, remote operation from 10 to 80 meters

6. Small footprint and movable with wheels.

The following points should be noted for environmentally friendly dust-free water mist sandblasting machines:

(1) Sandblasting distance: refers to the linear distance between the end face of the sandblasting nozzle and the surface of the substrate. As the sandblasting distance increases, the erosion effect of the abrasive on the substrate surface weakens, and the abrasive is dispersed. The selection of this parameter depends on the sandblasting method, air pressure, and the specific situation of the workpiece. A suitable distance can achieve a certain surface roughness and high sandblasting efficiency, while avoiding significant compressive stress on the surface caused by abrasives and avoiding deformation of the workpiece. Generally controlled within the range of 100-300mm. The pressure or sandblasting distance is longer than the suction type.

(2) Sandblasting angle: refers to the angle between the axis of the abrasive jet and the surface of the substrate, which should be maintained within the range of 60-75 degrees and avoided at 90 degrees. To prevent sand particles from embedding into the surface.

(3) Air pressure: The pressure supplied by compressed air to the inlet of the sandblasting device. As the pressure increases, the abrasive spraying speed increases, the surface erosion effect intensifies, and the abrasive crushing rate increases. Therefore, the selection of pressure should consider the requirements of abrasive thickness, workpiece thickness, and surface roughness. Pressure sandblasting generally ranges from 0.3 to 0.5Mpa, while suction sandblasting ranges from 0.5 to 0.6Mpa. Pressure sandblasting should consider the pressure loss caused by the longer sandblasting pipe, and the pressure should be appropriately increased.

(4) Sandblasting nozzle aperture: When the air pressure is constant, the nozzle aperture increases, resulting in an increase in air consumption and sand production, and an improvement in sandblasting efficiency. The selection of aperture is limited by the air supply, usually 8-15mm. Due to wear, when the aperture of the sandblasting nozzle increases by 25%, a new nozzle should be replaced.

(5) The movement speed of the sandblasting gun: By relative movement between the sandblasting gun and the surface of the workpiece, a uniform coarsening surface is obtained. There are no strict requirements for movement speed, and the sandblasting time is mainly controlled based on the uniformity of surface roughness. Excessive sandblasting time can lead to unwanted surface structures

Sa3 level is equivalent to SSPC-SP5 level in the United States, and is a high processing level in industry, also known as white cleaning level (or white level). The technical standard for Sa3 level treatment is the same as Sa2.5 level, but 5% of shadows, defects, rust, etc. have to exist.

The rust removal and sandblasting machine is mainly used for removing oxide scale, welding slag, corrosion layer, old paint, dust, etc., while increasing the adhesion of the coating and enhancing the service life of steel structures, reaching the SA2, 5-3.0 cleaning level.

Environmental friendly dust-free water mist sandblasting machine Applicable scope:

It is widely used in water conservancy, ships, valves, petroleum, thermal spraying, pipelines, agricultural machinery, anti-corrosion engineering, steel structures, oil tanks, bridges, large molds, field anti-corrosion, stone lettering, renovation of ancient buildings, glass fiber reinforced plastics and other spray pretreatment.

Metal workpiece surface cleaning, surface pre-treatment, surface cleaning, cleaning all surface residues such as rust, oxide skin, oil stains, old paint layers, welding slag, impurities, etc. on the surface of the metal workpiece.

At the same time, create appropriate roughness and roughness on the surface of the metal workpiece to increase surface adhesion.

The environmentally friendly dust-free water mist sandblasting machine consumes less sand and water:

1.When sandblasting with high-performance abrasives, approximately 0.5-1.0 liters of water are used per minute. Working continuously for 8 hours a day requires only 0.24 to 0.48 tons of water for sandblasting.

2.Compared to traditional sandblasting machines that use no less than 900 kilograms of abrasive, our equipment uses approximately 35-80 kilograms of abrasive per hour. Working non-stop for 8 hours a day only requires 0.28-0.64 tons of abrasive.

3.Due to the lubrication effect of water, the service life of the nozzle of the air water sand equipment is longer than that of dry spraying. Under the same air volume and pressure, the work efficiency of air water sand is slightly better than that of dry sand blasting, with lower sand consumption and better economic benefits.

4. Different abrasives can be selected according to different application needs. For example, garnet, quartz sand, river sand, etc.

5.Among various common abrasive materials, garnet is the most widely used in the field of air water sand paint removal and rust removal due to its highest density and hardness.

6. Adopting air water sand technology, the excellent dust reduction effect directly avoids the hardware and time costs of investing in protective facilities for dry sandblasting operations, greatly reducing the requirements for the construction environment, and adapting to the vast majority of indoor or outdoor operations.