Liangshi Intelligent (stock code: 837430), as a leading supplier of surface treatment and coating equipment systems in China, provides a sandblasting room, spray painting and drying room system for a certain company. The size of the sandblasting room and spray painting and drying room is L20000 × W7000 × H6000mm, the workpiece is transported using a rail trolley, with a maximum weight of 40 tons. Mainly used for surface sandblasting, painting, drying, and heavy-duty anti-corrosion coating of various steel structural components, castings and forgings, pipelines, bridge and ship structural components, wind power components, and mechanical equipment structural components.

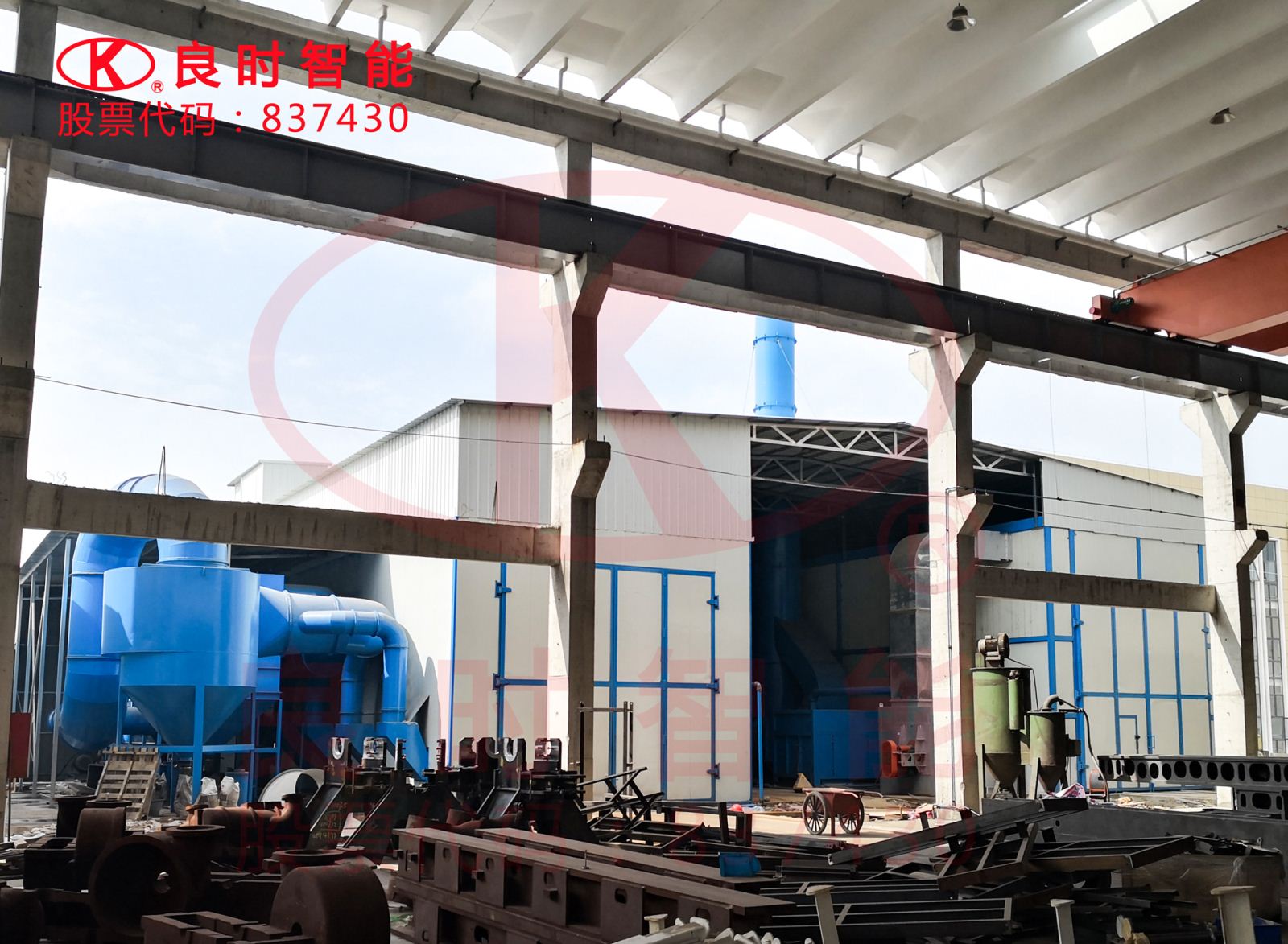

Shanghai Liangshi Intelligent Environmental Protection Sandblasting Room Spray Painting and Drying Room System

The sandblasting room system includes one sandblasting room body, four belt conveyors, one bucket elevator, and one full curtain shot dust separator, one sand storage box, two dual gun high-efficiency electric remote controlled sandblasting machines, one cyclone separator, one high-efficiency filter cartridge dust collector, and one three-level high-efficiency filter, one maintenance and repair platform, one lighting system, and PLC centralized electrical control system.

The paint drying room system includes 1 set of paint drying room body, 2 sets of paint mist filtration system and 2 sets of VOC treatment devices, 2 sets of electric heating hot air circulation system and supply air filtration system, 2 sets of exhaust explosion-proof fans and exhaust chimney, 1 set of explosion-proof lighting system and 2 sets of organic waste gas concentration detection alarm devices, and 1 set of PLC centralized electrical control system.

The sandblasting room system is equipped with two high-efficiency electric remote control press type double gun sandblasting machines. This sandblasting machine is equipped with a 10mm high-speed boron carbide nozzle, and the sandblasting efficiency of each gun can reach 20m2/h; After sandblasting, the workpiece reaches cleanliness levels Sa2.5~Sa3.0, sandblasting roughness reaches Rz25~75um, and sandblasting coverage rate reaches 100%. The dust removal system of the sandblasting room adopts three levels of dust removal and filtration: the first level of large cyclone dust removal and filtration+the second level of high-efficiency filter cartridge dust removal+the third level of high-efficiency filter. The internal circulation is unorganized and the fan is controlled by frequency conversion. The overall sandblasting room system achieves advantages such as safety, quality, efficiency, energy conservation, environmental protection, and intelligence.

Interior view of spray painting drying room during spray painting processing

The spray painting and drying room system is equipped with one high-pressure airless spraying machine and one air spraying equipment, and the paint application rate can be controlled at around 50%. When painting, the top static pressure layer is used for uniform air supply, and the bottom dry filter is used for air extraction. The entire painting room is in a slightly negative pressure state; During drying, the electric heating hot air circulation method is adopted, with uniform air supply through filtering at the top and return air filtering at the lower side; The perfect spray painting and drying room process equipment and strict spray painting quality process control ensure that the surface paint coating quality of the workpiece spray painting processing reaches an excellent level, with a coating thickness of 100um~300um.