Sand suction machine / dehumidifier / heater series dehumidifiers

Dehumidifier

Shanghai Liangshi painting dehumidifiers classification

According dehumidification principle —— single refrigeration, single wheel, frozen runner associative

According to the structure of the way —— the whole body type and sub

According heating —— electric type and steam type

According Cooling —— air-cooled and water-cooled type

Different functions according to the principle of division

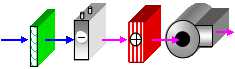

1.single refrigerant dehumidifier:

1.single refrigerant dehumidifier:

Cooling by a compressor, the air is cooled to the dew point temperature, water separation, and then the air is heated to reduce the relative humidity. The device is suitable for the South or the hot and humid conditions.

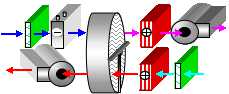

2.single dehumidifier:

2.single dehumidifier:

Using absorbent silicone wheel made of moisture in the air adsorption and separation, to achieve dehumidification purposes. The device is suitable for low temperature and humidity at the north or climatic conditions.

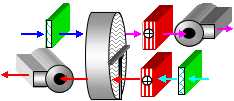

3.wheel modular refrigeration dehumidifier:

3.wheel modular refrigeration dehumidifier:

Climatic conditions for the four seasons, winter cold, summer heat, apricot days of wet conditions and design, is a single runner organic combination or single frozen dehumidifier, applicable to any environment.

According to the structure, installation division

|

Name |

Overall dehumidifier |

Sub-size dehumidifier |

|

Air volume |

Air volume 3000~22000 m3/h |

Air volume 6000~60000 m3/h |

|

Place of use |

Open space spraying, dockspraying |

Fixed spray room |

|

Installation method |

Mobile use, with cables and hoses can be used round |

Stationary use, indoor and outdoor unit connected to brass, hard charge air |

|

Overall Structure |

Container structure, rain crash |

Spraying cold rolled sheet, steel structure |

|

Advantages |

mobile, easy to use,Compact structure |

Large air volume blowing, easy maintenance, reduce room noise |

Electric heaters

Is a popular international high-quality long-life electric heating equipment. For the flow of liquid, gaseous medium, heating, insulation, heating. When the heating medium under pressure by an electric heater heating chamber, using fluid thermodynamics take enormous heat evenly heating element produced work that is heated medium temperature reaches a user process requirements.

Electric heater features:

1、small size, big power.2, fast thermal response, high precision, high overall thermal efficiency.

3、he heating temperature is high.

4、the media outlet temperature uniformity, high precision temperature control.

5、a wide range of applications, adaptable.

6, long life and high reliability.

7、can be fully automated control, upon request by the heater circuit design, can easily achieve the outlet temperature, flow, pressure and other parameters of automatic control, and with the machine computer networking.

8、significant energy saving effect, the heat energy generated almost 100% pass heating medium.

Gas (oil) heater

With natural gas or diesel fuel as a heat source, heat pipe conduction heating gas; widely used in coating line, printing and dyeing, leather, wood drying, food, pharmaceutical, chemical and modern farming, aquaculture or central hot air heating systems.

Features:

1.low operating costs, compared with electric heaters, steam heaters preparation of hot air, the cost savings of more than 30%;

2.superconductor using finned heat pipe heat, warming fast, compared with tubular heaters, air and flue gas mixed string there is no problem;

3.heat transfer efficiency up to 85%, the air temperature can be set within 60-80 ℃;

4.combustion systems using advanced automatic control technology, features automatic fault protection, automatic detection of display, overheat protection and other functions;

5.heat transfer process in non-polluting, clean hot air can be prepared, environmental performance indicators have reached the international advanced level of similar products;

6.device structure is compact, small, practical and beautiful, significant benefits, is one of the best hot air preparation products.

Main components:

GRRF series of fuel (gas) heater is a new product developed by the company in recent years. It absorbs the foreign latest heat pipe technology, the speed and efficiency of heat transfer greatly improved thermal underutilized energy to get significant savings. While using a foreign import combustion device, so that the oil or gas combustion sources that save energy and reduce pollution emissions. The use of advanced control technology enables the safe use of equipment to get a reliable guarantee.