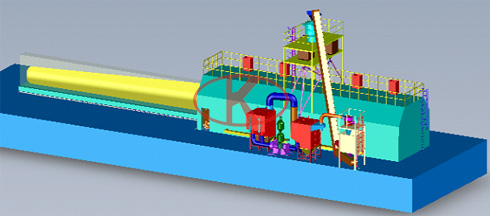

Aircraft wing NC peen forming equipment

NC peen forming machine (CNC aircraftwing peen forming equipment)

Peen forming is a complex aerodynamic preferred method of forming the curve. This non-molding process for forming an airplane wing is the best, this process can also be used to remove distortions due to machining complex parts or heat generated by deformation.

Shot peening the surface of the wing of the aircraft can be used to shape and enhance its lifting performance, and improve fuel economy and reduce pollution.

By this molding process by shot peening one side of the residual compressive stress under the effect of deformation in the elastic range.This deformation makes muster shot by one side, this will force the other side of the arch is also a state of compression. This precision control and professional design technology to make the wing surface to form any desired fluid curves. After blasting parts will increase the combat capability of bending fatigue.Although only one side blasting process, but both sides have had a residual compressive stress.This compressive stress corrosion cracking resistant parts and fatigue.

Peen forming process is suitable for a variety of surface curvature, thickness and shape requirements, as well as ribs and deformation processing conditions.

Peen forming a repeatable way to save money, many commercial aircraft manufacturing molded wings. Because no mold, no need to leave allowance is molding material, and can save the expensive mold development and production costs.

Aircraft wing NC peen forming equipment