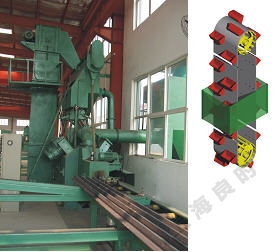

Steel Shot Blasting Production Line

Elevator guide rail / steel roller conveyor shot blasting machine |

Elevator guide rail / steel roller conveyor shot blasting machine :

The set of elevator guide rail shot blast cleaning production line using a continuous roller conveyor mode, upper and lower parts by PLC automatic control, the shot blasting equipment can effectively eliminate stress rails to prevent deformation of the rear rail planed to remove the rail scale, enhanced paint adhesion, with good effect; mainly used to clean up the elevator to strengthen the solid rails, rails and other elevator components hollow.

The series shot blasting equipment with high efficiency, high speed blasting, shot blasting large, high degree of automation, long life and easy replacement of wearing parts and other characteristics;

Suitable for narrow-band profiles workpieces batch shot blasting and strengthening treatment.

|

|

Pass type shot blasting pretreatment line

|

Pass type shot blasting pretreatment line:Pass type shot blasting pretreatment line profile is determined by preheating, shot blasting, painting and drying process which is widely used in shipbuilding, automobiles, bridges, machinery, container and other industries plates, profiles and structural parts surface rust, paint, assembly line.

Mainly used in buildings, bridges and other industries with large word-beam, high H-beam steel structure size to eliminate stress and surface rust cleaned.

Maximum workpiece size: 15000×800×1600mm

Roller conveyor speed: 0.5-4 m/min

Shot volume: 250×8 kg/min

Shot Round:8

Total ventilation: 18000 m3/h

Total power:125kw

Total weight: 22.5T

Dimensions: 30000×5500×9300mm |

|

Steel and steel roller conveyor pass type Shot Production Line

|

Special - shaped steel tube roller pass type shot blasting production line

|