Sonics metal wire, ceramic rods spraying equipment

Sonics metal wire / ceramic rods melt ejection spray gun

In order to obtain a special functional coating (typically dense or high hardness of the metal coating), or restricted workpiece conditions required to obtain a special functional coatings, can choose to use supersonic wire gun: using oxygen propane gas as a heat source, special feature of the melt coating of the atomizing gas transportation and delivery of the atomized droplet surface, to obtain the desired.

Because you can use larger diameter materials specifications, the work has the characteristics of high efficiency, high quality.

Supersonic ceramic rods spraying equipment is the use of ceramic rods as raw , melting in the oxy-acetylene flame ,atomized into particles by compressed air, jet on the surface to form a coating.It is an inexpensive, stable quality, easy-to-spraying, after spraying the workpiece wear it particularly good, for example chromium oxide, wear resistance, even better than the plasma spraying.

Low investment and quick results, the system equipment is increasingly being used to prevent corrosion, wear and high temperature coatings.

Material classification and uses:

1、Alumina: The color is white, melting point 2050 ℃. Because of its high hardness, wear-resistant coatings are used as mechanical seals, piston, shaft parts and other occasions, but also to acid, alkali and salt corrosion.

2、Aluminum titanium hybrid ceramic, with the increase of TiO2, coating from light grey to black , melting at about 1800 ℃. Lower coating porosity, good finish after polishing, the use does not generate static electricity, so aluminum, titanium ceramic coating is used extensively for textile, printing and dyeing industries.

3、Zirconia: color is dark green, dense coating, polished finish very well, has good chemical stability, is insoluble in acids, bases, salts and other solvents, the coating so heavily used in various corrosive mediums, it's hardness is very high, cobalt and tungsten carbide can be used for wearable occasions.

4、Zirconia: The color is white, melting point 2500 ℃, high temperature insulation systems for aerospace engine.

Right: LSQTB-2 ceramic rods melt ejection gun

Metal wire/Ceramic rods melt ejection system auxiliary equipment:

|

Name |

Explanation |

|

Feeding speed controller |

Input AC220V,50Hz |

|

Compressed air system |

Category I level 3 compressed air pressure 0.8Mpa flow ≥3m3/h |

|

All types of gas source |

Oxygen, acetylene gas |

|

Pressure control meter |

Recommended: YQD-370,YQE-213 gas regulator |

|

Gun clamping mechanism |

Depending on the specific circumstances: the general use of manual operations, joint automatic slewing mechanism is completed |

|

Workpiece clamping mechanism |

|

Ventilation and dust removal |

Tailor-made |

|

Sand blasting machine |

Selected according to specific circumstances |

Supersonics ceramic powder melt ejection equipment

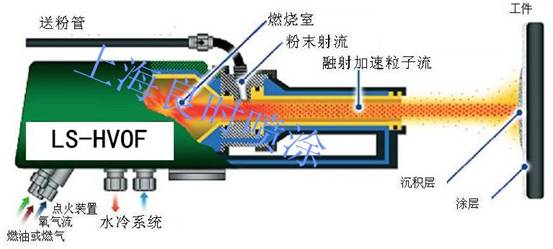

Image:Supersonics ceramic powder melt ejection principle

Sonics melt ejection with a high-speed, low temperature, deposition rate, high bonding strength, good reduction properties of the material, the coating composition of the advantages of easy to control, it is widely used in metallurgy (eg, roller, shaft wind turbine blades), Chemical (valves, reactor, pipes, axes), electricity (four boilers, fan blades), petroleum (oil pump, pistons, hydraulic plunger shaft), paper and printing (calender rolls, machine roller, coating roller , dryer, reeling drum, knives), general machinery (shaft, disk, ball parts), and other areas.

>LSBY3000 Sonics ceramic powder melt ejection system

Propane - oxygen mixture combustion for heat, suitable for spraying a variety of metal and alloy powders, especially for spraying carbides (eg WC / Co, Cr3C2 / Ni-Cr), nitride powder. HVOF is widely used in metallurgy (eg, roller, shaft wind turbine blades), chemical (valves, reactor, pipes, axes), electricity (four boilers, fan blades), petroleum (oil pump, pistons, hydraulic plunger shaft), paper and printing (calender rolls, machine rollers, coating rollers, cylinders, rolls rolls, tool), general machinery (shaft, disk, ball parts), and other areas.

System consists of the following main parts::

1Supersonic melt ejection spray gun;

2Powder feeding system;

3Control systems;

4Compliance of standard pipe, water pipe, cable.

Image:BY3000 Sonics ceramic powder melt ejection system

Technical performance parameters:

|

Component |

Features |

Content of the project |

Basic parameters |

LSBY3K

Control system |

Can realize the spraying process automation, and real-time monitoring of the system, dynamic control airbrush work processes, to respond to system failures immediately. |

Control type |

PLC control |

|

Propane pressure/flow |

0.6~0.7Mpa 65~100L/min |

|

Oxygen pressure/flow |

1.2Mpa 150~170L/min |

|

Air pressure/flow |

0.7~0.8Mpa 300~350L/min |

|

Hydrogen pressure |

0.35Mpa(Ignition uses) |

|

Dimensions / Weight:600ⅹ600ⅹ1760mm;130kg |

LSBY3F

Powder feeding system |

Using nitrogen gas to feed powder, powder falling from the powder feeding tube, with the rotation of the turntable to reach the powder outlet, together with powder feeding gas into the powder feeder away with gun. |

Powder feeding method |

Binoculars scratch disc |

|

Monocular volume |

2.5L |

|

Powder feed gas |

Nitrogen |

|

Powder feed gas pressure |

1.3Mpa |

|

Powder feeder traffic |

10~14L/min |

|

Powder feed velocity |

0~150g/min |

|

Powder feeding accuracy |

±3% |

|

Spraying powder size |

5~200um |

|

Dimensions / Weight:500ⅹ280ⅹ1260mm;110kg |

BY3000

Supersonic melt ejection spray gun |

Using propane as fuel and oxygen as combustion gases, air and water cooled. The entire ignition process, adding hydrogen to make ignition easier to implement. |

Flame speed |

2100m/s |

|

Flame temperature |

2700℃ |

|

Spray gun power |

100KW(Conversion value) |

|

Powder particle velocity |

550~650m/s |

|

Maximum powder feed velocity |

150g/min |

|

Cooling method |

Water + air cooling |

|

Cooling water flow |

9.5L/min, 0.3Mpa |

|

Minimum coating porosity |

1% |

|

Maximum bond strength |

70MPa |

|

Spraying powder granularity |

10~45um |

|

Dimensions / Weight:330ⅹ230ⅹ50mm;2.7kg |

|

Cable piping |

Compliance of standard pipe, water pipe, cable. |

|

Cooling system |

0.2Mpa 9.5L/min(Self-made), water (medium) |

LSBY3000 auxiliary equipment

|

Name |

Explanation |

|

Compressed air systems |

Category I level 3 compressed air pressure 1.0Mpa flow ≥3m3/h> |

|

All types of gas source |

1.2Mpa oxygen, nitrogen, hydrogen 0.35Mpa, propane 0.75MPa |

|

Pressure adjustment meter |

Recommended : YQD-30, YQY-30, YQQ-30 & nbsp; gas regulator |

|

Gun clamping mechanism |

Depending on the specific circumstances: the general use of robotic systems, combined with automatic slewing mechanism is completed |

|

Workpiece clamping mechanism |

|

Ventilation and dust removal |

Tailor-made |

|

Sand blasting machine |

Selected according to specific circumstances |