Alloy powder melting transmitting device

This equipment employs oxygen-acetylene flame as heating source ,with a variety of self-fluxing alloy powders or special thaw shot powder as the material .

Using oxy-acetylene gas mixtures and conveyed with compressed air metal powder is to shot suction principle.

Spray gun's main components:

1. Noumenon:it is the heart of the whole gun, connecting all parts of the body, oxygen - acetylene gas mixture through the body via the connecting pipe, nozzle exit.

2.Connecting pipe:The main role is to send the mixed gas to the nozzle evenly , connecting pipe sealed at both ends have a direct impact to the gun can work properly, while the connecting tube also play a role in connecting peripheral devices and air delivery nozzle.

3. Flame nozzle:it has three types,depending on different kinds of materials and the flame temperatures requirements to choose.

4. Air nozzles:it has four types,depending on different kinds of materials to choose;

5. Various types of gas switch:Compressed air, powder feed gas, powder flow rate control, control of oxygen, acetylene, such as total control and later switch;

6. Direction switch powder hopper with adjustable seats and storage tank

Image:Spot-priming powder into shooting gun

|

Serial number |

Project |

Data and instructions |

|

Model |

Regular fusion facial materials |

Application |

|

1 |

LSQTE-7h |

Various nickel, copper, iron-based, cobalt-based self-fluxing alloy powder, plastic powder |

Corrosion-resistant and insulating coating and preparation of some heat-resistant coating |

|

2 |

LSQTE-2000 |

Special alloy powder, part pure oxide |

|

General efficiency |

Continuous spraying of NI-based powder: about 7Kg/h |

|

Auxiliary equipment |

Security oxyacetylene and compressed air systems, sand blasting equipment, guns and other heavy melting |

With our constant flow of powder feeding technology, the auto-ignition technology and gas delivery and monitoring, automated industrial control and other aspects of development and progress, we will be able to provide users with reliable automatic melting of powder injection system equipment!

Such shoot-suck alloy powders into injection systems tailored to specific user, welcome to inquire!

Plastic powder special melting shooting equipment

Model LSPFS-1 Plastic powder flame spray gun system is based on a variety of special plastic powder as melt-emitting material,using oxygen (combustion) + flammable gas as a heat source,the plastic powder shot smoke introduced into the flame zone heating, and with a certain speed spraying to stacked on workpiece surface ,and then heated to make plastic-coated surface is moist, dense smooth and continuous corrosion-resistant coating.

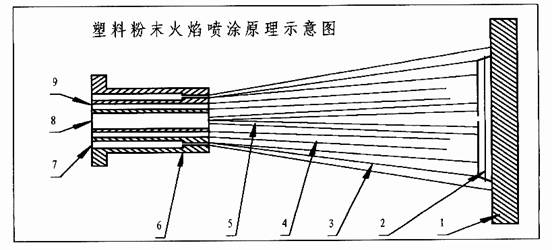

Image: the reason of plastic powder spray equipment form a dense coating

1.Spraying the workpiece;2.Spray coating;3.Flame flame flow;4.Shielding gas flow;5.Plastic powder + gas;

6.Nozzle;7.Oxygen gas imports;8.Powder + gas imports;9.;Cooling and shielding gas imports

Image:Thaw shot plastic powder spray gun

In various industrial fields, especially in the petrochemical industry, anti-corrosion requirements for energy increasing, the use of special anti-corrosion plastic material, can solve special steel parts and special anti-corrosion requirements for tank products.

Model LSPFS-1Plastic powder flame spraying equipment is composed of spray gun, powder feeder, pipeline and air valve.

Model LSPFS-1 Plastic powder flame spray gun is based on a variety of exclusive plastic powders as spraying materials, adopts oxygen - acetylene flame, propane gas, liquefied petroleum gas as heat source gas. Oxygen - gas mixing and distribution of various types of boiling powder of the spray gun are based on the jet - absorption principle

All-positionAdvanced design and high-precise process make Model LSPFS-1 plastic powder flame spraying equipment work continuously, stably on various occasions .The spray gun adopts powder feeding device of high performance to ensure the spray gun for spraying of all-position. It can be operated more portably and efficiently than imported products.

StabilityHigh-performance external powder powder feeder stable, uniform delivery of various types of plastic powder, to ensure the stability and consistency of performance coatings and coating thickness

General applied materials: chlorinated polyether nylon, low-pressure polyethylene, polypropylene, polyphenylene sulfide , epoxy powder,etc.