The sandblasting room system mainly consists of the following parts: sandblasting room body, shot collection hopper, belt conveyor, bucket elevator, sand separation device, sandblasting machine, dust removal system, air supply system, electrical control system, maintenance platform, grid board, escalator, and folding lifting gate.

Requirements for surface treatment of wind power equipment before painting:

1. No oil or moisture; 2. No rust or oxides; 3. No adhesive impurities; 4. No acid, alkali or other residues; 5. The surface of the workpiece has a certain roughness.

Hoisting machinery/elevator environmental sandblasting room

Large underground water curtain spray booth and drying leveling room

Large logistics transportation equipment - Dry open air spray painting room system

Drying and solidification system for large-scale logistics transportation equipment

.jpg)

Dual use room for lifting machinery/elevator environmental protection painting and drying

Large scale casting ground rail conveying water spinning spray painting room

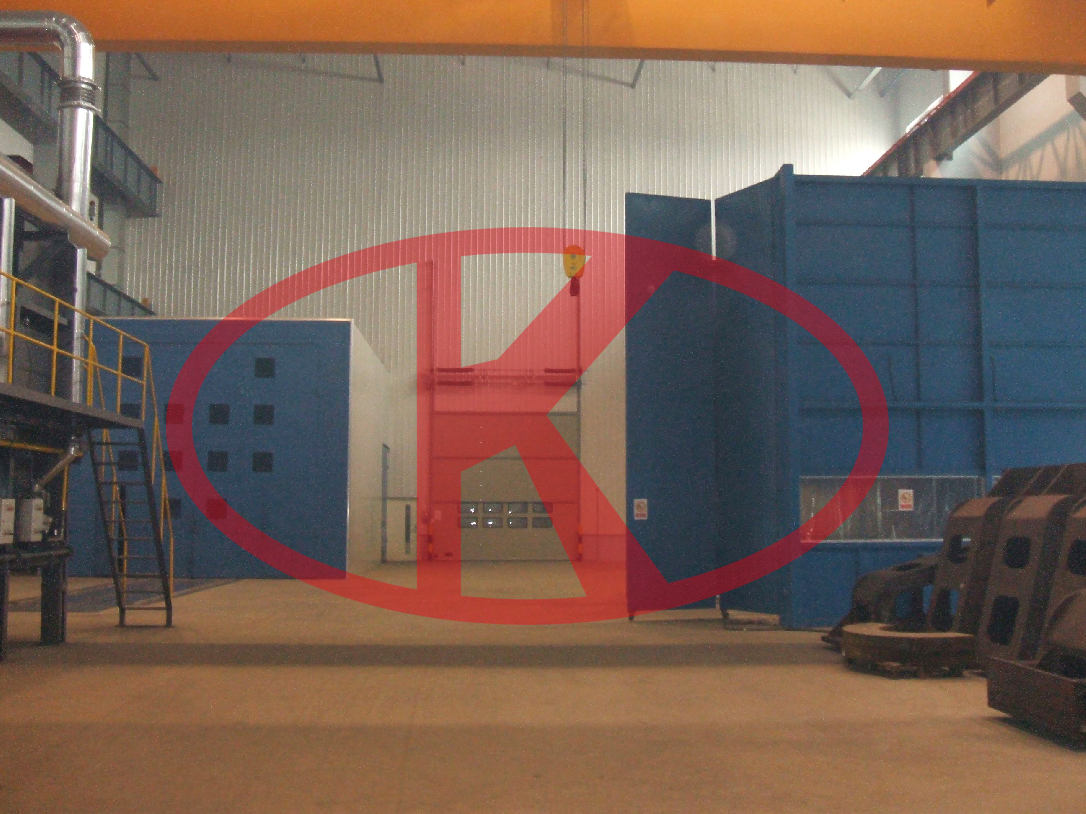

Large turbine machinery environmental protection sandblasting room and spray drying dual purpose room

Marine pipe fittings spray painting and drying dual-use room

Pump body environmentally friendly dry spray booth

Environmental protection sandblasting room and spray painting room for tank storage tanks

Wind power bearing automatic sandblasting room zinc spraying room spray painting room drying room system

Dry spray painting room and spray drying dual purpose room for injection molding machinery

Electric equipment environmental protection sandblasting room spray painting room

Environmental protection power generation boiler heat exchanger sandblasting

spraying ground rail conveyor sandblasting room spray painting room

.jpg)

Environmentally friendly automatic paint dipping room

.jpg)

Environmentally friendly petroleum machinery spray drying integrated room

大型燃气加热烘干房

.jpg)

Regarding Liangshi Intelligence:

Liangshi Intelligent (stock code: 837430) is located in the Lingang New Area of China (Shanghai) Pilot Free Trade Zone. The production base of Liangshi Intelligent Lingang New Area covers an area of 84 acres (approximately 56000 square meters) and has first-class customer information sources and product marketing channels. Its products are sold to more than 20 countries worldwide.

Liangshi Intelligent has passed the Sira International Quality Management System certification and ISO14001 Environmental Management System certification in the UK, and has obtained more than 30 utility model patents and invention patents. Its affiliated company Shanghai Liangshi Pressure Vessel Manufacturing Co., Ltd. has obtained a special equipment design license (number: TS1231092-2017, engaged in the design of D1 and D2 pressure vessels), Special Equipment Manufacturing License (No. TS2231129-2016, engaged in the manufacturing of D1 and D2 pressure vessels), and has formed close cooperation with major universities. Relying on high-tech, relying on high-quality products and excellent after-sales service, we have created good economic and social benefits.

Shanghai Liangshi Intelligent Technology Co., Ltd. provides surface treatment system solutions to global customers with over 20 years of experience. It is a professional manufacturing and automation intelligent control system integration company that integrates research and development, design, manufacturing, engineering installation, and engineering consulting. It can provide customers with:

1. Surface treatment shot blasting, shot strengthening equipment, thermal spraying and coating equipment process system solutions and process equipment;

2. Automation and robot application process system solutions and process equipment;

3. Integrated solutions for pressure bearing systems in the fields of food and dairy products, pharmaceuticals, biology, refrigeration, petrochemical, shipbuilding, energy, paper making, textile systems;

4. Coating environmental protection equipment: VOC exhaust gas, wastewater, dust treatment and noise control system process solutions and equipment.

The leading products of the enterprise are as follows:

Main business: Design, research and development, production, and sales of surface treatment engineering system integration.

Six main products: automated coating production lines, intelligent robot spraying systems, automated shot blasting production lines, intelligent robot shot blasting strengthening systems, automated thermal spraying systems, and energy-saving and environmental protection equipment for coating.

The products are mainly used in fields such as new materials, new energy, engineering machinery, automobile manufacturing, containers, ship and ocean engineering, aerospace, port and bridge, electronic and electrical, environmental engineering, printing and papermaking machinery, medical machinery, textile machinery, etc.

Main customer groups: aerospace carriers, land and navy military industry, automotive locomotives and high-speed trains, petrochemical power, shipbuilding and port machinery, new materials and new energy, heavy industry equipment, agricultural machinery engineering machinery and mechanical manufacturing equipment, etc.

The surface engineering system integration produced by the company has the characteristics of intelligence and automation, which can achieve automatic control of industrial production processes, and therefore belongs to automation equipment. According to the definition of high-end equipment in the "Twelfth Five Year Plan" for the high-end equipment manufacturing industry, "it mainly includes high-tech and high value-added equipment required for the transformation and upgrading of traditional industries and the development of strategic emerging industries." The company's products belong to high-end equipment and are strategic industries that provide technical equipment for other industries in the national economy.

For more information, please visit www.shliangshi.com

Tel: 021-5103520068913886

Emergency service: 18918186798

National service: 400-021-5767

Fax: 021-68907128

Email: webmaster@shliangshi.com