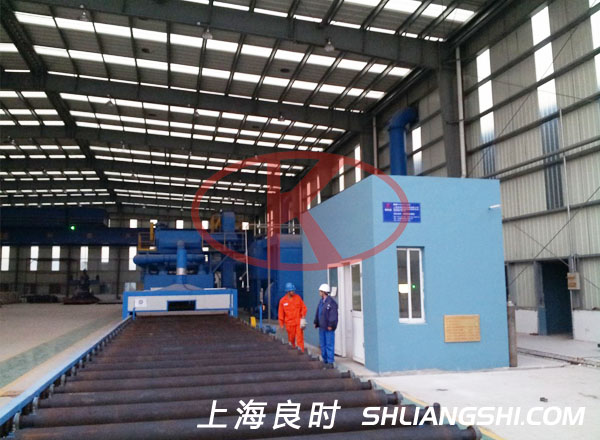

Shot blasting pretreatment line for steel plate in equipment manufacturing industry:

Shot blasting pretreatment line is making use of centrifuge force produced by the impeller of shot blaster at the time of rotating at high speed, eject the abrasives to the treated steel surface at very high speed, to impact and grind, remove the oxide layer and rust.

The shot blasting is efficient, it can be done in closed condition, configuring dust suction device to prevent environment. Besides, by match with automatic coating device, it can remove rust-paint prime paint integrated and automatic production.

Steel plate/ section steel shot blasting line

Steel plate shot blasting line has two types: one is steel plate shot blasting line, another is section steel pretreatment line. The working principle of both is the same, as the surface of section steel is complicated, the ramming head positioning of shot blaster should have a certain angle, and the width of section steel should be less than the width of steel plate.

Shot blasting, painting, drying pretreatment line:

Shot blasting is making use of centrifugal force by impeller of shot blaster when rotating in high speed, eject the abrasives to the treated steel surface at very high speed, to impact and grind, remove the oxide layer and rust.

The shot blasting is efficient, it can be done in closed condition, configuring dust suction device to prevent environment. Besides, by match with automatic coating device, it can remove rust-paint prime paint integrated and automatic production

SHLS successively for dozens of domestic shipyards provide steel plate pretreatment line, coating equipment and coating room design, manufacture and installate. Our customers contain COSCO Shipyard, Dalian Shipbuilding Heavy Industries, Jiangnan Shipyard, Hudong Zhonghua Shipyard, Jiaolong Heavy Industries.

Shot blasting line for steel plate of wind energy towers |

.jpg)

Shot blasting and painting, drying line for ship steel plate |

Shot blasting and painting, drying line for ship steel plate |

.jpg)

Shot blasting and painting, drying line for ship steel plate |