Sanding and sandblasting room | Liangshi creates container beauty secondary sanding production line system equipment for a well-known listed international group company in Vietnam

Shanghai Liangshi Intelligent (stock code: 837430), as a leading domestic supplier of container sanding and beauty painting equipment system solutions, recently provided complete sets of container beauty secondary sanding production line system equipment for well-known listed international group companies in Vietnam. Currently, the installation and commissioning of the system equipment for the container beauty secondary

sanding production line has been successfully completed, and has received unanimous praise from this company for our Shanghai Liangshi Intelligent!

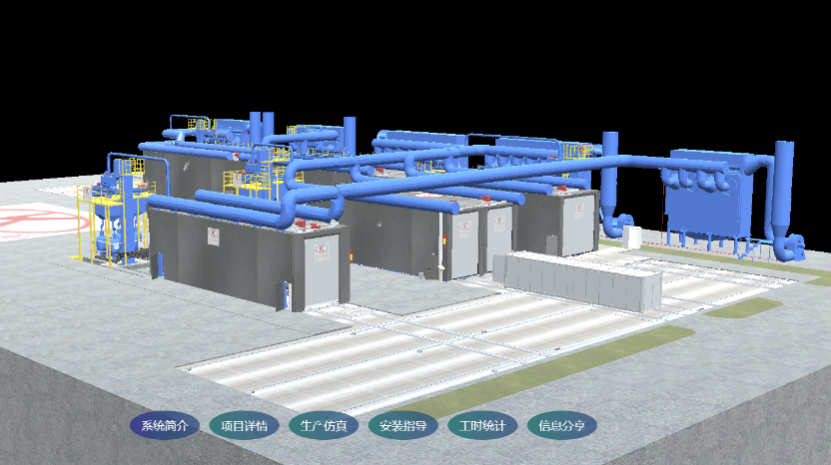

Shanghai Liangshi Intelligent Co., Ltd. is a well-known listed international group company that has carefully built a complete set of equipment for the container beauty secondary sanding production line, which has many advantages such as safety, high quality, efficiency, energy conservation, environmental protection, and intelligence. The automatic sanding system of the container beauty secondary sanding room system equipment uses a multi gun continuous automatic sanding tank host and a complete set of automatic sanding mechanisms inside and outside the box. The abrasive recovery and sorting system uses mechanical abrasive recovery and sorting equipment such as a horizontal belt conveyor, a vertical bucket elevator, and a shot dust separation cloth distribution machine (with advantages of stability, efficiency, energy conservation, and environmental protection). The sanding and dust removal system uses a high-efficiency filter dust collector, The electrical control system adopts PLC+MES intelligent management system and production management process digital twin technology.

%20(1).jpg)

This set of intelligent container beauty secondary sanding production line provided by Shanghai Liangshi Intelligent is currently the first * * container automatic production line in Vietnam. The container production line has the ability to automate the production of 20 foot, 40 foot, and 45 foot containers, and the container production cycle time is 108 seconds/TEU, 120 seconds/FEU. The container secondary sanding production line has excellent automatic sanding and cleaning effects for container welds, with a sandblasting cleaning grade of Sa2.5 and a roughness of Rz50~60um; Provide a good foundation for pre-treatment and sandblasting cleaning for the cosmetic coating of containers in the subsequent process, thereby ensuring the high standard requirements for container production quality.

(1).jpg)

It is worth mentioning that this container beauty secondary sanding production line project uses Shanghai Liangshi Intelligent Digital Twin Technology to complete a digital model of the project's plant and production line before it is built. In order to simulate and simulate the factory in a virtual digital space, and transfer the real parameters to the actual factory construction. After the completion of the workshop and production line, they can still continue to interact with each other in daily operation and maintenance.

In the future, with the improvement of Liangshi's artificial intelligence and digital technology, it will cover more product lines, meet customers' needs for simulating device operation conditions, real-time viewing and collecting device data, and AI intelligent optimization of device operation solutions, so as to achieve the goal of reducing costs and increasing efficiency.

Our company has successfully designed and manufactured the system equipment for the container beauty secondary sanding production line for many well-known enterprises at home and abroad (please call 021-51035200 for details). The company has established a comprehensive service system for the design, manufacturing, installation, and training of the container beauty sanding production line. We will provide cost-effective products Excellent and timely service to provide customers at home and abroad with one-stop comprehensive intelligent manufacturing surface treatment coating system solutions.